Created just for flasks 2 in 1 Stirrer & Seal

The new LABEDA Sealing Mixer is for researchaers who need a stirring solution for flasks. It´s compact and light weight body offers both mixing and sealing in just one device. The Sealing Mixer provides a high reliability and usability to support your daily tasks in research and development.

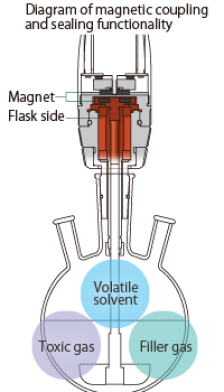

1. High sealability is provided by a magnetic coupling

A magnetic coupling is used for power transmission from the motor. The bulkhead and the O-ring of stirrer enable sealed mixing of the flask. Non contact rotaiting of the stirring rod with a magnetic force provides high sealability. It is suitable for experiments using volatile organic solvents and for mixing filling gas in the flask. The drive parts are not in contact with the O-ring. Therefore, a deterioration in sealability due to wear of the parts will not occur. Leakage is avoided, even with long operation, and generating abrasion powder is prevented. This unit provides reliability and safety for laboratoory work.

2. Stable mixing by using the stirring impeller

Open / close stirring impeller enables stable mixing.

Sealablity inside the flask and experiment reproducibility are both achieved.

While a magnetic stirrer is incapable of mixing high viscosity fluid, The stirrer can be easily used for mixing high viscosity fluid and for reactions that may generate deposite.

Chemical / heat resistant PTFE materials are used for the unit parts.

The originally developed shaft fixation mechanism holds the stirring rod firmly. Slipping of the rod or drop off of the rod during mixing is avoided. Feel free to inquire if a special form or

material for the rod or stirrer is required!

3. A high usability improves the daily laboratory work efficiency

Just fit the unit to the standard taper of the flask. A seal is not required for assembly. Therefore, installation can be done in a short time. Shaft alignment is not required either, and the heavy unit does not require moving. Easy handling is enabled for all. A tapered joint with a different diameter is available (optional) in addition to the standard taper size (29/42). Each Part can be easily assembled / disassembled without requiring tools. Contamination from residual chemicals can be avoided by washing the parts regularly.

4. The sealing mixer can be used in a variety of applications

PTFE or ceramics are used for the wetted parts. Chemical / heat resistant materials cover a wide range of applications.Since the stirrer and the seal are compact, space saving installation in the fume food is achieved. Operation from the outside of the fume food is possible since the controller is separeted. The rotation can beset per 1 RPM, helping reproduce experiment procedures. A revolutionsas low as 2 RPM can be set. Mixing by controlling the damage to the biological tissue or product is possible. An off timer that can be set per 1 minute is provided.

Technical details:

Max. rotational torque: 0.2N・m

Rotation speed: 2~450RPM

Recommended Pressure: 61kPa~Amb.

(gage pressure:-40kPa to 0kPa) Joint size29/42

Standard stirring shaft: High loadable PTFE stirring rod・General φ8 shaft* general spacer(MG-0-J) & cap(MG-0-K) are required.

SizeMain unit:φ72×255mm

Contoroller:80×188×52mm

*Stirring rod and cable excluded WeightMain unit:approx. 1.2kg

Controller:approx. 500g

*Stirring rod and cable excluded

Input100~240V 50/60Hz